Laboratory Equipments

Tools for Advanced Materials Research and Fabrication

Finite Element Analysis: Workstation with Abaqus 2025

For finite element analysis, our lab is equipped with a powerful workstation featuring a 13th Gen Intel® Core™ i9-13900KF processor running at 3.00 GHz, 64 GB of RAM, and a 24 GB graphics card. This high-performance setup, combined with an Abaqus CAE 2025 license, enables efficient and detailed simulation of complex composite and fiber metal laminate structures with enhanced speed and accuracy.

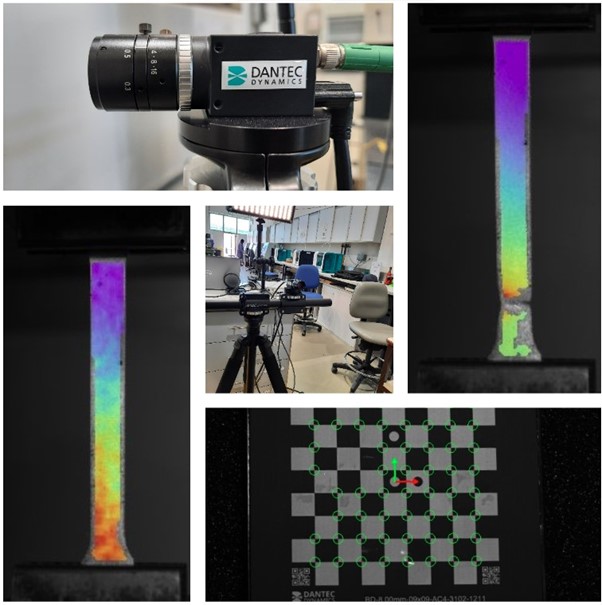

DIC Setup

Our lab is equipped with a Dantec 2D Digital Image Correlation (DIC) setup, which is used for precise, full-field strain measurement during mechanical testing. This non-contact optical system enables accurate tracking of deformation patterns on the specimen surface. The DIC system is integrated with a Universal Testing Machine (UTM) manufactured by MTS, with a load capacity of 100 kN, allowing for high-precision mechanical characterization of composite and fiber metal laminate specimens under various loading conditions.

Hand Lay-up Method

In our lab, the fabrication of FRP composites and Fiber Metal Laminates (FMLs) is primarily carried out using the hand layup method. This versatile and cost-effective technique allows for precise control over fiber orientation and stacking sequence. A variety of fabrication tools are available to support the process, including rollers, brushes, and cutting instruments. Additionally, a hot press is available for the controlled curing of composite materials, ensuring uniform temperature and pressure conditions for improved mechanical performance and structural integrity.

Sandblasting Equipment

In our laboratory, sandblasting equipment is used to create mechanical surface roughness on metal plates for the fabrication of Fiber Metal Laminates (FMLs). The setup includes an assembly of a Black & Decker pressure cylinder, a sandblasting chamber manufactured by Switzer, and a sandblasting gun. The system allows for precise control of surface texture through adjustable parameters such as nozzle size, pressure, and the distance between the gun and the target surface. This flexibility makes it suitable for achieving various levels of surface roughness tailored to specific fabrication requirements.

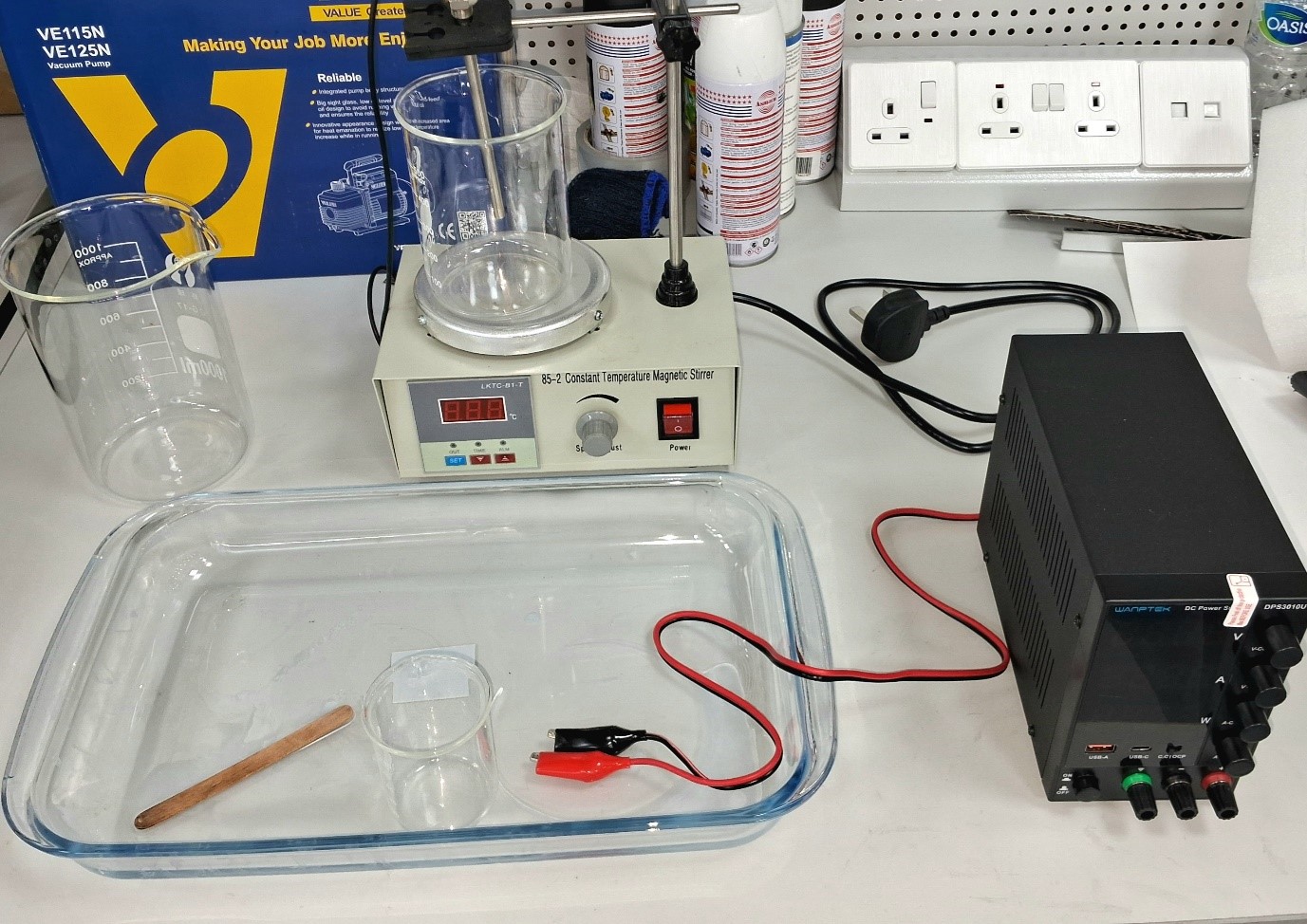

Electrochemical Surface Etching

A small setup is designed in our lab for creating electrochemical surface etching on metal plates to develop controlled surface roughness. The setup consists of an AC to DC converter supplying up to 12 volts, chemical handling beakers and trays for safe electrolyte use, and a temperature-controlled magnetic stirrer to ensure uniform agitation during the etching process. This system enables the creation of various electrochemical surface roughness levels by adjusting voltage, temperature, and chemical composition.

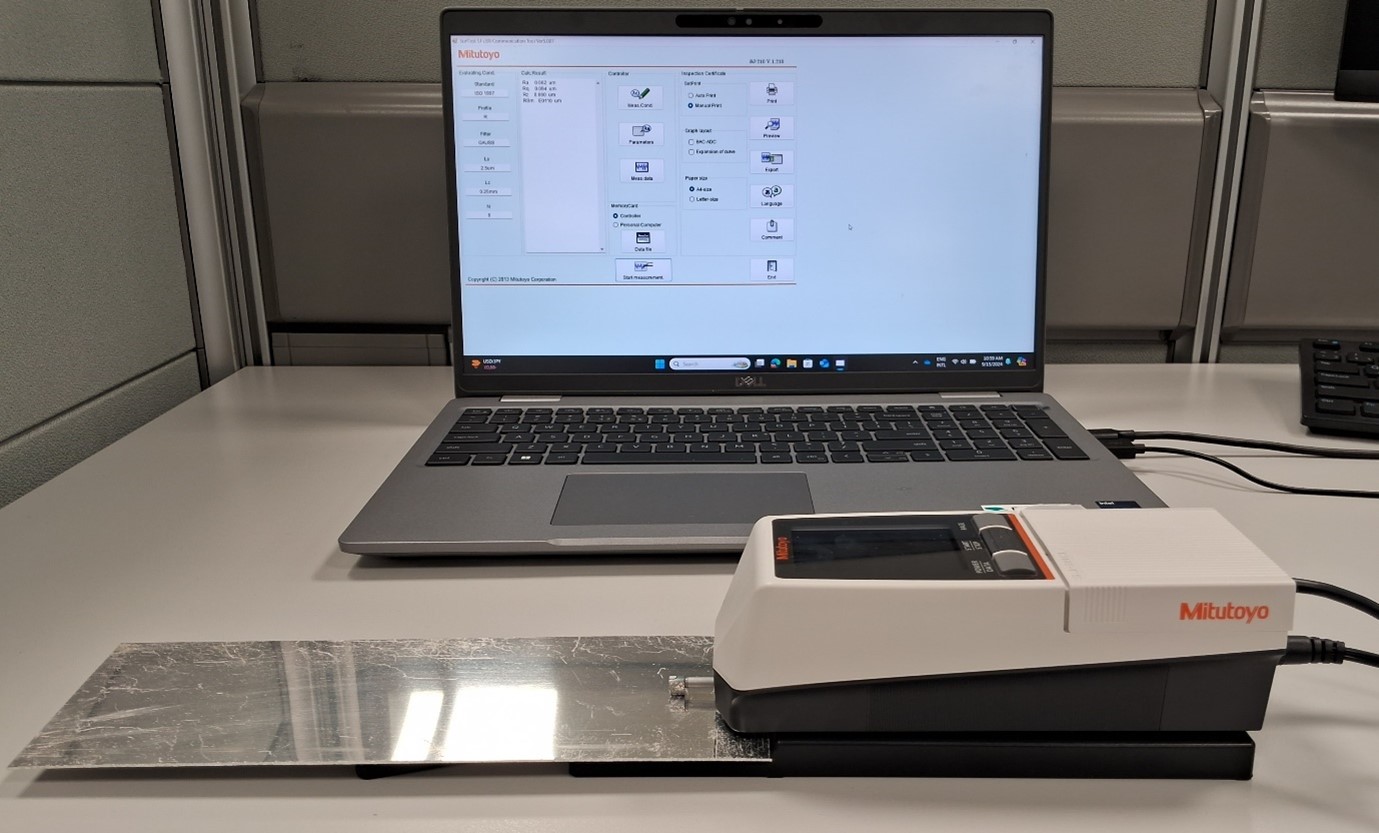

Mitutoyo Surface Roughness Tester

Our lab is equipped with the Mitutoyo Surface Roughness Tester SJ-210, a portable and highly precise instrument for measuring surface texture. It allows for accurate evaluation of surface roughness parameters such as Ra, Rz, and others, making it essential for quality control in surface preparation processes. With its easy-to-use interface, LCD display, and data storage capabilities, the SJ-210 is used to assess both mechanically and chemically treated metal surfaces, ensuring consistency and reliability in the fabrication of Fiber Metal Laminates and composite materials.

Ultrasonic Cleaner

Surface cleaning at various stages is a crucial step in the preparation process, and for this purpose, our lab is equipped with an ultrasonic cleaner. A key advantage of this equipment is its ability to handle and thoroughly clean large specimens up to 200 × 200 mm in size, making it highly suitable for cleaning metal plates used in the fabrication of Fiber Metal Laminates (FMLs). The ultrasonic action ensures the effective removal of contaminants from the surface without causing damage.

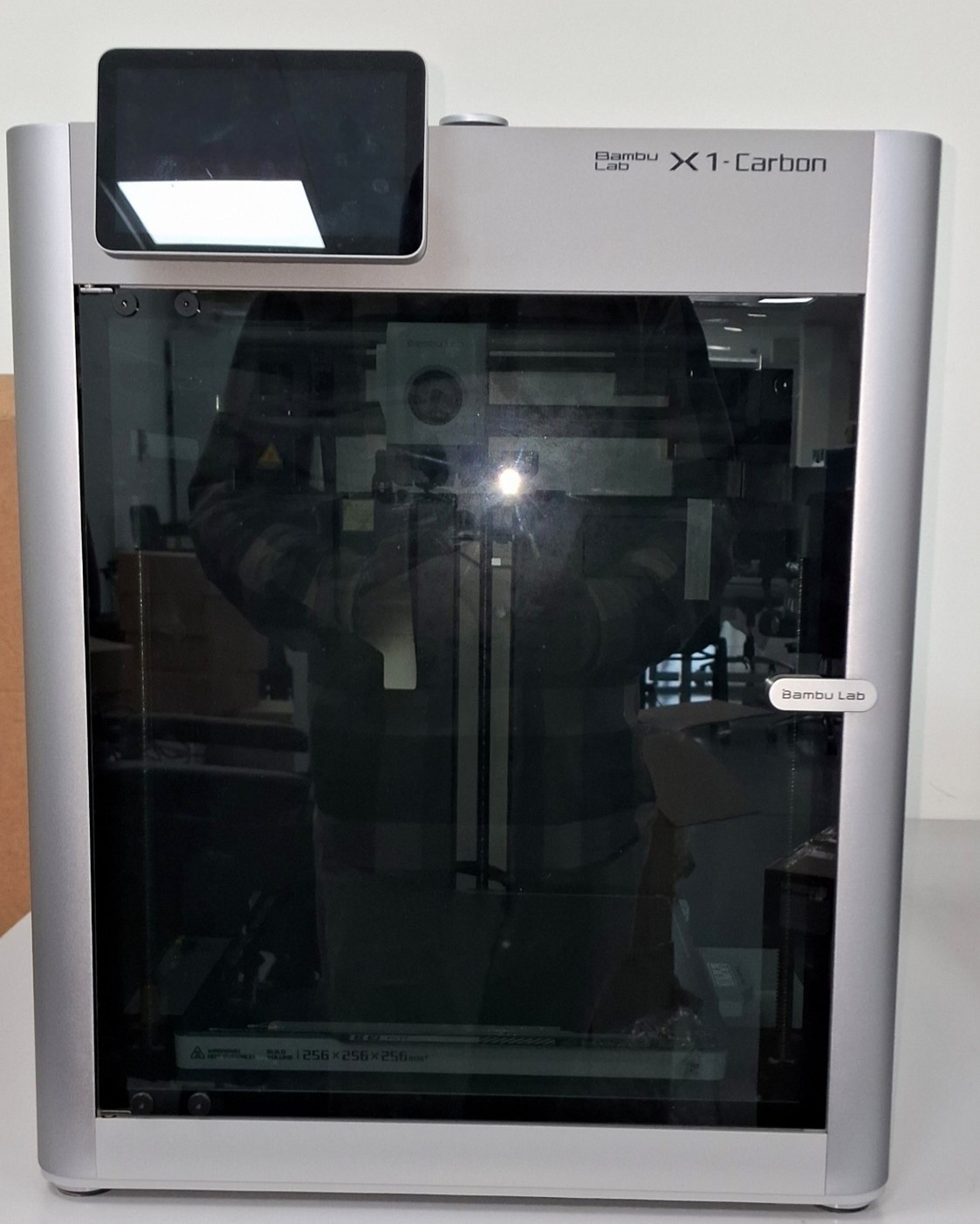

Bambu X1 3D Printer

Our lab is equipped with the Bambu Lab X1 Carbon 3D printer, which combines industrial-level performance with user-friendly operation. This advanced printer is ideal for rapid prototyping, functional engineering components, and high-quality multi-material prints. Its speed, precision, and versatility make it suitable for both experienced users and beginners seeking reliable and professional results.

Elegoo Laser Engraver

Our lab is equipped with the Elegoo 10 W laser engraver, a precise and versatile tool ideal for engraving and light cutting applications. With a spacious 400 × 400 mm working area and support for a wide range of materials including wood, leather, and acrylic, it enables high-speed, high-resolution fabrication. Its advanced safety features, user-friendly interface, and compatibility with LightBurn software make it a valuable asset for prototyping, labeling, and custom fabrication tasks in our research and development activities.